More precise production

Using modern technologies will surely influence the quality of a molded part. Fewer rejects and less downtime will occur when the production process is precisely controlled. The result is a higher profitability.

The ever faster developing of new technologies shows the available potential in new developments. Even new production equipment installed few years ago can today be out dated and no longer competitive because of certain new applications and the ongoing fast technical developments. In the reality very often the production technology is surpassed by the fast development of new final products.

Latest state-of-the-art developments in control technology and hydraulics have helped to improve the precision and by this the economic efficiency of the injection molding process. The basis for this is a solid and robust machine construction together with a compact design - as with BOY injectin molding machines.

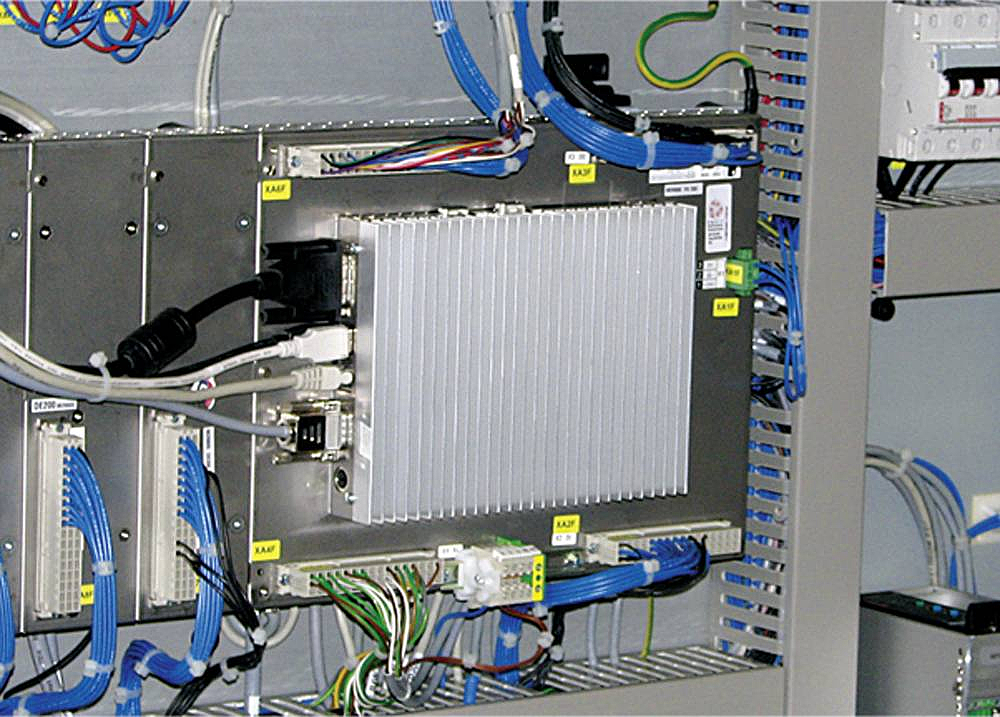

State-of-the-art control technology - a faster way to attain continuous quality

As early as 1994, the first control in the Procan series was introduced to the market. The Procan ALPHA® incorporates various new developments. Above all, these are related to ease of operation, reaction speed, and process safety.

Hydraulics and mechanical engineering

The use of the "right machine" for an application results in precise parts and maximum efficiency. Also the reliability of the injection molding machine plays an important part to avoid machine defects and to minimize part rejects.