Clamping systems from BOY

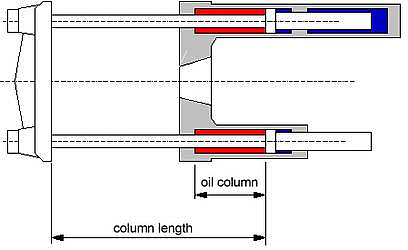

The very first machine model, the BOY 15, featured already the innovative two-platen clamping system. Piston rods with three bearings pull the moving platen towards the fixed platen where the clamping cylinders are integrated. This design allows for a cantilevered clamping unit and when compared to conventional three-platen systems, offers great floor space advantages. By applying the clamping force via the four tie bars an even distribution of clamp pressure over the entire surface of the mold fixing platen is achieved. This has special advantages for molds with high cavitation respectively for molds with asymmetrical positioning of cavities. The small oil volume in the BOY two-platen clamp system results in a very rigid clamping system. The distances between tie bars and platens, which are very generous for this clamping force range, enable a flexible production even with very large and complex standard molds. The clamping system developed by BOY features very few moving parts. This reduces costs not only for the investment, but also regarding machine maintenance. Furthermore, this minimizes wear and thus maintenance time. BOY's clamping system enables fast and flexible adaptation to all requirements. Easy access, short operating cycles, and quick retrofitment guarantee highest efficiency when using BOY injection molding machines.

BOY: Continous optimimization for innovative injection molding technique

During the last 50 years, about 50.000 injection molding machines up to 137.5 tons were sold worldwide. BOY injection molding machines require less space compared to other competitive models due to their compact design. Furthermore, the freely accessible two platen locking system enables the flexible use of molds and offers many possibilities for automation and integration of BOY machines into production lines.

Access to all machine components is easy. Set-up times are correspondingly short and the maintenance of BOY injection molding machines is uncomplicated. The Procan ALPHA control enables an intuitive machine operation with touch-screen operation, graphic menu navigation, and fast screen start-up. With the new servo pump drive, BOY machines require 50 % less energy, cooling power is also minimal and the noise level during production is considerably quieter. These and other advantages demonstrate that BOY stands for economy, efficiency, innovation and "Made in Germany" quality.