Highest precision

BOY 35 E

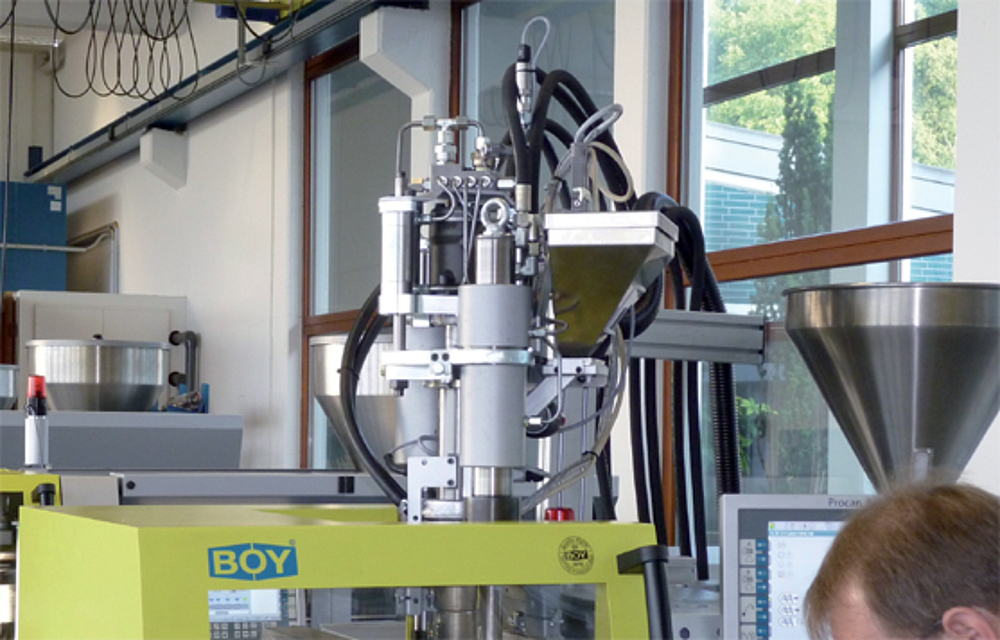

The BOY 35 E is a four-tie bar, fully hydraulic reciprocating screw injection molding machine with two-platen clamping unit and swivel-out injection unit.

With its rigid clamping system and the high efficiency of the injection unit, the well-proven injection molding machine is ideally suited for the production of precision parts within a narrow tolerance range.

With a required floor space under two square metres, the BOY 35 E is more than just the most compact machine of its type; the price/performance ratio, too, is unparalleled.

With the indisputably lowest machine hour rates, the BOY 35 E is in no danger of having its top position threatened.

Six different sizes of injection units combined with six different screw diameters allow individual adaptation of the machine performance, according to the processing needs.

Facts

- Injection molding machine

- compact design

- only 3040 square in footprint

- 38.5 US tons clamping force

- Servo-Drive

- two-Platen-clamping unit

- maximum efficiency

- maximum quality

- lower energy demand

- maximum precision

- flexible use of molds

- comfortable operation

- Procan ALPHA 6 control

- easy automation

- worldwide service

Specifications

| Euromap Size: 350-16 / 350-45 / 350-56 / 350-81 / 350-96 |

| Screw Diameter: 14, 18, 22, 24, 28, 32 |

| Max. Stroke Volume: 4.67 in³ |

| Max. Injection Flow: 4.31 oz / sec |

| Max. Spec. Injection Pressure: 39,726 psi |

| Max. Daylight Between Platen: 19.69 in |

| Max. Opening Stroke: 11.81 in |

| Distance Between Tie Bars: 11 x 10 in |