Convincing facts

Besides a continuous improvement in precision and in consequence improvement in quality a decisive point is the economic efficiency of the production equipment. This is illustrated and made clear with the following examples.

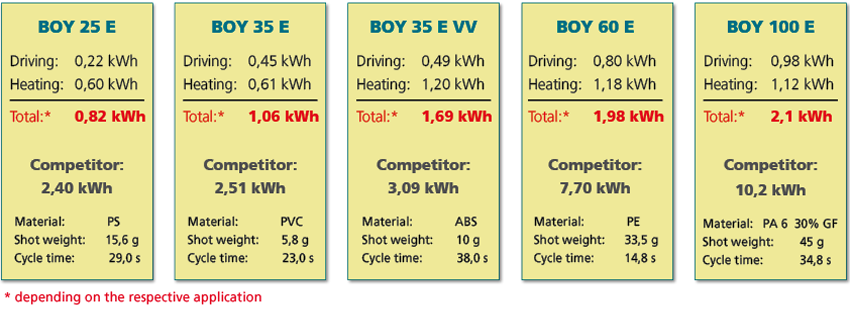

Energy consumption and cooling requirement

Comparison measuring show clearly that the E-series with the servo-drive enable a part production with 50% less energy consumption.

The use of the EconPlast further on reduces the energy requirement for the plasticizing by further 50%.

We would be glad to check the energy consumption on your machine.

Compared to competitive machines, BOY injection molding machines use considerably less energy. The servo-motor pump drive will save 50 percent energy compared to other drive technologies - and even more - than that, depending on the application.

Due to the low current consumption and the effectively designed hydraulics system, the cooling requirement is extremely low.

Operating and set-up times

The operation of BOY injection molding machines is very easy and clear, due to the intuitive and fast operation via Windows-oriented touch-screen surface. This is a time and cost advantage for the user which should not be undervalued. For many years, BOY control systems have been leading with regard to precision, information, and operation. Easily accessible two-platen clamping systems also ensure rapid mold changes.

Low space requirement

Due to the extremely compact design of all BOY injection molding machines, the actual space needed is reduced by almost one third. Thus, more machines can be placed in the same space. Rather than invest in more production space, you may use the money for your production means.

Peripheral equipment can be placed on top or below the machine and within the machine's footprint. Very often, no additional space is required.

Investment and operating costs

Cost is certainly another consideration. The purchase of a reliable BOY injection molding machine, which are well known for their low operating costs is the best decision.

Overall, the operating costs play a much more important role than is generally assumed. During the long machine life, only about 20 % of the total machine costs are investment costs. More than 80 % of the entire value are needed for the operation itself. With regard to those follow-up costs, the user should consequently take advantage of the saving potential that presents itself by selecting the right machine.

Summary

Calculation examples of machine hours rates of BOY injection molding machines illustrate the low operating costs. Depending on the machine configuration used, the operating costs calculated per hour of production are markedly lower than those for competitive or older machines.

Low hourly rates, short retrofit kit: efficient injection molding machines made by BOY

All BOY models are characterized by flexibility, precision and intuitive operation. Their suitability to automation enables the simple integration to both complex production processes and clean room applications. Comprehensive service, energy efficient drive concepts and absolute economic efficiency and with the use of the EconPlast units - BOY can offer its customers convincing solutions for any application in the injection molding industry through continuous advancement.